Product Description

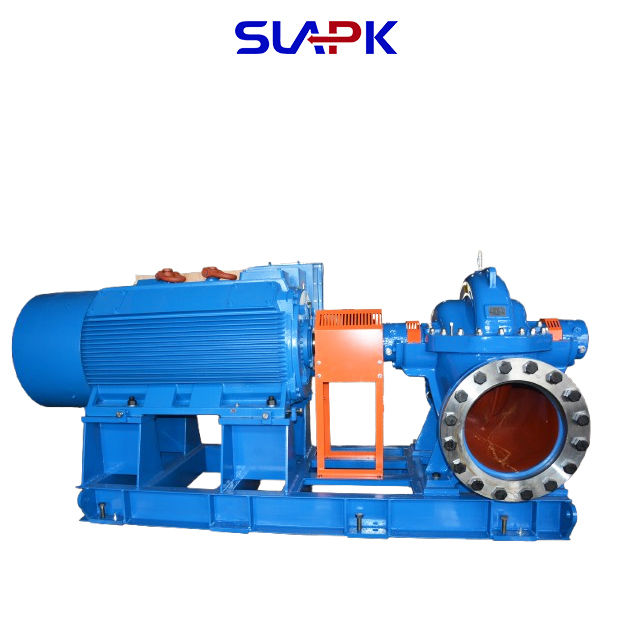

22kw 126m3/h 33.5m head Split Casing Pump High efficiency Desalination

22kw 126m3/h 33.5m head Split Casing Pump Product Overview

A split case pump, also known as a single or double suction centrifugal pump, is primarily characterized by its ability to handle large flow rates and medium head. The working principle of the split case pump is as follows: the impeller is installed inside the pump casing and securely fastened to the pump shaft, which is directly driven by an electric motor. The center of the pump casing is equipped with a liquid suction port connected to the suction pipe. Liquid enters the pump through the foot valve and suction line. The discharge outlet on the pump casing is connected to the discharge piping.

When the pump operates at a constant speed, its head and flow rate are determined by the impeller diameter.

This series of pumps is specifically designed for industrial, municipal, construction, and large-scale water supply systems. With excellent energy efficiency and stable performance, these pumps are widely used in various high-demand applications.

Whether in urban water supply, wastewater treatment, cooling circulation systems, or agricultural irrigation projects, this high-efficiency split case pump delivers durable and reliable power support.

22kw 126m3/h 33.5m head Split Casing Pump Product Parameters:

Flow Range: 0.8 m³/h ~ 120 m³/h

Head Range: 5.6 m ~ 330 m

Temperature Range: -20°C ~ 120°C

Type of Liquid Transported: Various clean water and mildly corrosive liquids

Pump Chamber Pressure Resistance: ≤ 4.0 MPa

22kw 126m3/h 33.5m head Split Casing Pump Core Advantages

✅ Energy-Efficient Performance

Equipped with an advanced hydraulic model and optimized flow passage design, our pump achieves efficiency levels 5%–10% higher than similar products, significantly reducing energy consumption and operating costs.

✅ Split Case Structural Design

The pump casing adopts a horizontal split-case structure, allowing easy access for maintenance. Key components such as the impeller and shaft seal can be serviced without removing the inlet and outlet piping, saving time and maintenance costs.

✅ Durable Construction with Strong Adaptability

Manufactured using high-strength cast iron or stainless steel, the pump offers excellent resistance to corrosion and wear, making it suitable for various complex water quality environments and ensuring long-term stable operation.

✅ Low Noise Operation

Precision dynamic balancing, combined with high-quality bearings and sealing components, effectively reduces operational noise and improves working environment comfort.

✅ Smart Control Compatibility

Supports frequency conversion control and remote monitoring interfaces, fully compatible with PLC systems to meet the requirements of modern intelligent water management.

Due to the water is a little salt, with corrosive. So we suggested SS316 material. This material is anti-corrosive, reasonable cost.

After calculated by our engineer, the TDH (Total Dynamic Head) is 60 meters.

The pump model is OS200-370-60HP(45KW) with flow rate 600GPM at head 60 meters, 4 pole,1750RPM, power supply 3phase 380V 60HZ, with packing seals. Because the hot weather, the seawater will evaporate, leaving solid salt particles during operation. In this situation, packing seals is better than mechanical seals for seawater pump.

After 40 working days, the test and production work has finished.

After 30 days waiting, the goods have arrived at Manila at 12th, August. The customer is satisfied with the good outlook and performance.

Split case water pump parameters:

(Notice: We will choose one suitable split case type according to your local site, inquiry, please)

| Type |

Capacity |

Head |

Motor power |

| split case pump |

m3/h |

l/s |

m |

kw |

| OS80-210 |

131 |

36.4 |

60.5 |

37 |

| 164 |

45.6 |

55 |

| 197 |

54.6 |

50 |

| OS80-210 |

106 |

29.4 |

47.7 |

30 |

| 133 |

37.1 |

43.5 |

| 159 |

44.5 |

37 |

| OS80-270 |

80 |

22.2 |

21.3 |

11 |

| 99 |

27.8 |

19 |

| 120 |

33.3 |

17 |

| OS80-270 |

166 |

46.1 |

97.5 |

75 |

| 207 |

57.5 |

90 |

| 248 |

69 |

79 |

| OS100-250 |

230 |

64 |

83 |

90 |

| 288 |

80 |

75 |

| 346 |

96 |

67 |

| OS100-250 |

85 |

23.6 |

13.7 |

7.5 |

| 106 |

29.4 |

12.5 |

| 128 |

35.5 |

11.3 |

| OS100-310 |

242 |

67.2 |

98 |

110 |

| 302 |

83.9 |

90 |

| 363 |

100.8 |

80 |

| OS125-230 |

426 |

118.4 |

68 |

132 |

| 541 |

150.3 |

60 |

| 639 |

177.6 |

48 |

| OS125-300 |

397 |

110.3 |

97 |

160 |

| 497 |

138 |

88 |

| 596 |

165.6 |

75 |

| OS200-520 |

565 |

156.9 |

67 |

200 |

| 706 |

196.1 |

62.5 |

| 847 |

235.2 |

55 |

| OS250-480 |

800 |

222.4 |

50 |

185 |

| 1000 |

278 |

45.5 |

| 1200 |

333.6 |

38 |

| OS250-600 |

772 |

214.4 |

98 |

315 |

| 965 |

268.1 |

90 |

| 1158 |

321.6 |

80 |

| OS300-30 |

835 |

232 |

23.5 |

75 |

| 1044 |

290 |

19.8 |

| 1253 |

348 |

15 |

| OS300-560 |

1258 |

350 |

68 |

355 |

| 1573 |

437 |

62 |

| 1888 |

524 |

54 |

| OS300-700 |

1388 |

386 |

147 |

900 |

| 1735 |

482 |

136 |

| 2082 |

578 |

125 |

| OS350-360 |

1354 |

376 |

32 |

160 |

| 1692 |

470 |

26.5 |

| 2030 |

564 |

20 |

| OS350-430 |

1987 |

552 |

27 |

220 |

| 2484 |

690 |

21.5 |

| 2981 |

828 |

15 |

| OS350-510 |

1786 |

496 |

57.5 |

400 |

| 2232 |

620 |

50 |

| 2678 |

744 |

40 |

| OS350-620 |

1020 |

283.3 |

94 |

560 |

| 1700 |

472.2 |

83 |

| 2150 |

597.2 |

69 |

| OS400-540 |

1110 |

308.3 |

54 |

315 |

| 1850 |

513.9 |

43 |

| 2340 |

650 |

33 |

| OS400-620 |

1440 |

400 |

94 |

710 |

| 2400 |

667 |

82 |

| 3020 |

839 |

66 |

| OS500-510 |

1465 |

407 |

31.3 |

220 |

| 2775 |

771 |

22.5 |

| 3600 |

1000 |

14 |

| OS500-700 |

1800 |

500 |

60 |

560 |

| 3005 |

835 |

49 |

| 3905 |

1085 |

35 |

Horizontal split case pump features:

1.High efficiency, lower noise

2.Rotor parts comply with API610

3.Rotation can be either Clockwise or Counter-Clockwise

4.Bearing lubricating is grease, oil type is also available

5.Impeller is balanced with ISO

6.Shaft seal can be either packing seal or mechanical seal

7.Rotation can be either Clockwise or Counter-Clockwise

8.Both can be interchanged, no need any modification

Split case pump materials:

1.Bronze, cast iron, carbon steels

2.Stainless steel 304, 316, 316L

3.Duplex stainless steel

4.Super duplex

FAQ

Q: How do I choose the right pump for my project?

A: We offer professional selection advice services. Simply provide us with basic information such as flow rate, head, and operating conditions, and we will recommend the most suitable pump model and needs clarification – possibly “supporting solution” or “matching configuration”) for your application.

Q: Is the equipment easy to maintain?

A: Yes! The split-case design allows for quick and simple maintenance, minimizing downtime and ensuring continuous production.

Q: Can this pump integrate with automated control systems?

A: Absolutely! Our pumps support standard signal outputs and PLC connectivity, meeting the demands of intelligent control systems.

Q:How to contact us?

A:We have a professional technical team that can recommend and provide the most suitable fountain pump product solutions based on your specific working conditions.

Our email is enquiry02@apkpump.com, our Whatsapp is +86 17537187726. Thank you for your inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!