Product Description

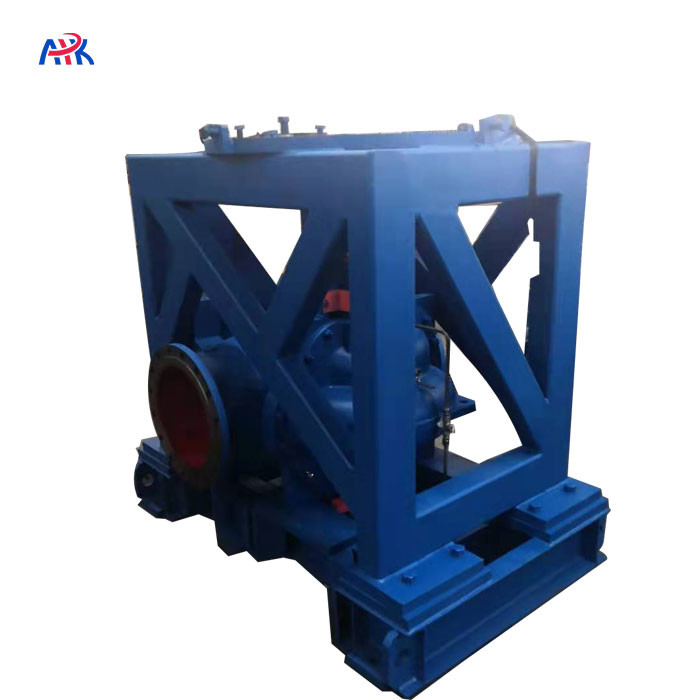

Double Suction Vertical Split Casing Drainage Raw Water Pump Dam Coal Fired Power Stations

Split case centrifugal water pump series are horizontal, single stage, axially split case, double suction, between bearing, centrifugal pumps. It’s suitable for pumping clean water or slightly contaminated water or liquids which is physically and chemically similar to water, where large quantity and certain head are required.

The axially split casing design makes it’s easy to remove the upper volute casing and rotary components without disturbing the motor and the pipework. And the double suction impeller ensures high efficiency.

Split case water pump types:

(Note: capacity, head meters, power supply and material, ODM OEM is available)

| Type |

Capacity |

Head |

Motor power |

| split case pump |

m3/h |

l/s |

m |

kw |

| OS80-210 |

131 |

36.4 |

60.5 |

37 |

| 164 |

45.6 |

55 |

| 197 |

54.6 |

50 |

| OS80-210 |

106 |

29.4 |

47.7 |

30 |

| 133 |

37.1 |

43.5 |

| 159 |

44.5 |

37 |

| OS80-270 |

80 |

22.2 |

21.3 |

11 |

| 99 |

27.8 |

19 |

| 120 |

33.3 |

17 |

| OS80-270 |

166 |

46.1 |

97.5 |

75 |

| 207 |

57.5 |

90 |

| 248 |

69 |

79 |

| OS100-250 |

230 |

64 |

83 |

90 |

| 288 |

80 |

75 |

| 346 |

96 |

67 |

| OS100-250 |

85 |

23.6 |

13.7 |

7.5 |

| 106 |

29.4 |

12.5 |

| 128 |

35.5 |

11.3 |

| OS100-310 |

242 |

67.2 |

98 |

110 |

| 302 |

83.9 |

90 |

| 363 |

100.8 |

80 |

| OS125-230 |

426 |

118.4 |

68 |

132 |

| 541 |

150.3 |

60 |

| 639 |

177.6 |

48 |

| OS125-300 |

397 |

110.3 |

97 |

160 |

| 497 |

138 |

88 |

| 596 |

165.6 |

75 |

| OS200-520 |

565 |

156.9 |

67 |

200 |

| 706 |

196.1 |

62.5 |

| 847 |

235.2 |

55 |

| OS250-480 |

800 |

222.4 |

50 |

185 |

| 1000 |

278 |

45.5 |

| 1200 |

333.6 |

38 |

| OS250-600 |

772 |

214.4 |

98 |

315 |

| 965 |

268.1 |

90 |

| 1158 |

321.6 |

80 |

| OS300-30 |

835 |

232 |

23.5 |

75 |

| 1044 |

290 |

19.8 |

| 1253 |

348 |

15 |

| OS300-560 |

1258 |

350 |

68 |

355 |

| 1573 |

437 |

62 |

| 1888 |

524 |

54 |

| OS300-700 |

1388 |

386 |

147 |

900 |

| 1735 |

482 |

136 |

| 2082 |

578 |

125 |

| OS350-360 |

1354 |

376 |

32 |

160 |

| 1692 |

470 |

26.5 |

| 2030 |

564 |

20 |

| OS350-430 |

1987 |

552 |

27 |

220 |

| 2484 |

690 |

21.5 |

| 2981 |

828 |

15 |

| OS350-510 |

1786 |

496 |

57.5 |

400 |

| 2232 |

620 |

50 |

| 2678 |

744 |

40 |

| OS350-620 |

1020 |

283.3 |

94 |

560 |

| 1700 |

472.2 |

83 |

| 2150 |

597.2 |

69 |

| OS400-540 |

1110 |

308.3 |

54 |

315 |

| 1850 |

513.9 |

43 |

| 2340 |

650 |

33 |

| OS400-620 |

1440 |

400 |

94 |

710 |

| 2400 |

667 |

82 |

| 3020 |

839 |

66 |

| OS500-510 |

1465 |

407 |

31.3 |

220 |

| 2775 |

771 |

22.5 |

| 3600 |

1000 |

14 |

| OS500-700 |

1800 |

500 |

60 |

560 |

| 3005 |

835 |

49 |

| 3905 |

1085 |

35 |

Split case raw water pump features:

1. Axially pump casing

The casing is axially split, the inline suction and the discharge nozzles are in lower half casing, these design makes it’s easy to remove the upper casing and rotary components without disturbing the motor and the pipework.

2. Dual Volute Casing

Pumps generating high heads have dual volutes to reduce radial forces, ensuring minimal shaft deflection and low bearing loads.

3. Between bearing design

Less shaft deflection due to the between-bearing design.

4. Wear Rings

Easily replaceable casing wear rings, protect the pump casing from the abrasion of impeller. Overall cost of operation is minimized.

5. Sealing Flexibility

Pump can be sealed by gland packing or wide range of mechanical seals.

Vertical installation of split case centrifugal water pump:

Split case centrifugal water pump applications:

Water transport

Water supply and distribution

Irrigation, drainage and flood control

District cooling/heating

Fire fighting

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!